Spiral Heat Exchanger Is Used for Which Services

These heat exchangers are commonly found in the Municipal Waster Water Industry as sludge heaters for anaerobic sludge digesters. Spiral heat exchangers are engineered and designed to be reliable and durable which can handle various heat transfer requirements.

No More Fouling The Spiral Heat Exchanger Process Heating

Whether its frequent fouling from dirty media or limitations from pressure drop and floor space they are the ultimate problem solver for liquid-to-liquid and two-phase duties.

. Spiral in both circuits removable heads on both sides for clean out. It is applicable to standalone spiral plate heat. A spiral heat exchanger is a useful alternative to shell and tube designs for many applications prone to fouling and plugging problems.

Bottoms to feed interchanger. Welded spiral heat exchangers. Installed with 15 12Ø 316 stainless steel coils.

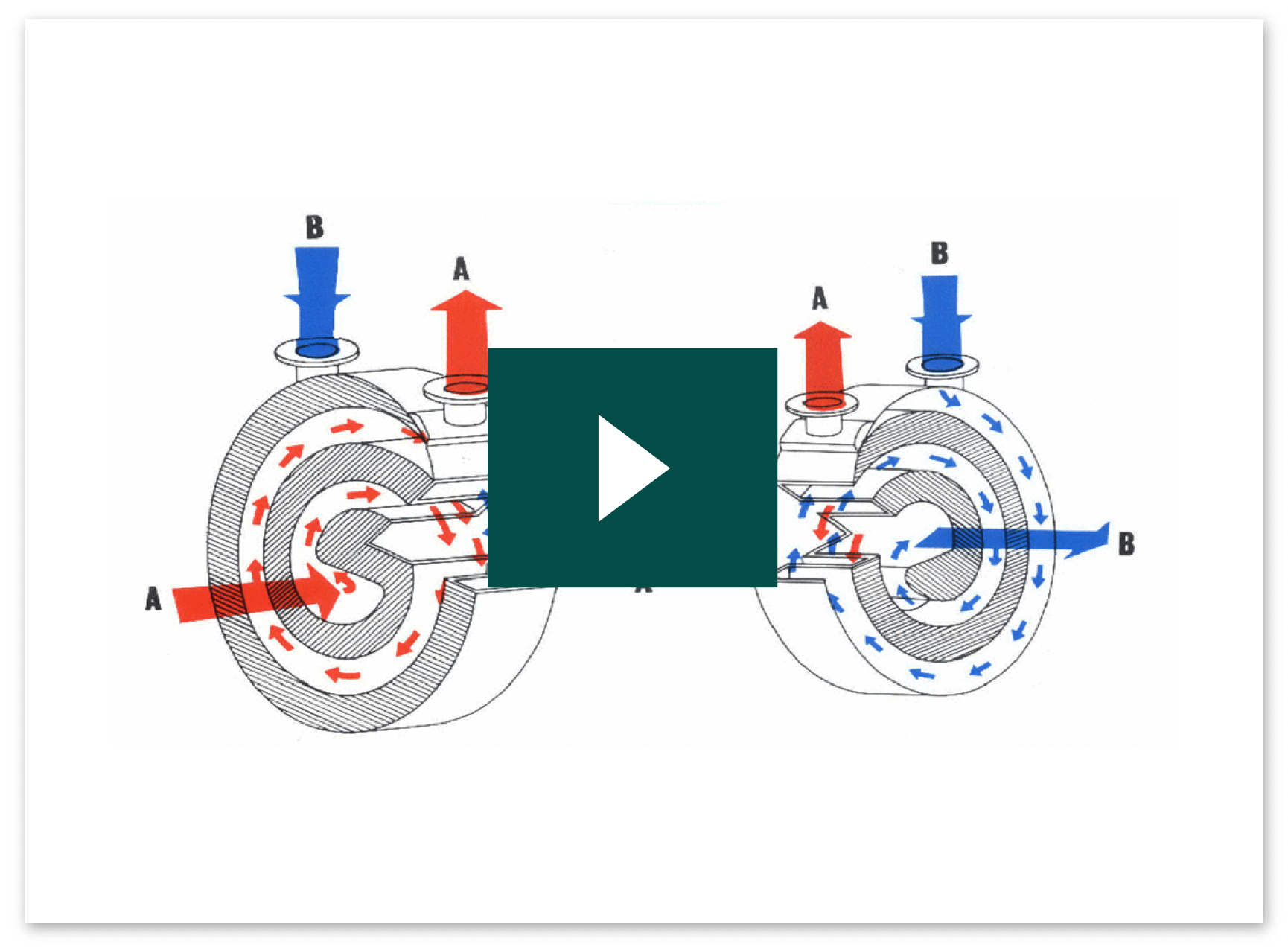

Used for fouling flows on both sides where cleaning of the prime surface is required. With a Type A both fluids are in spiral flow and in true counter flow. 300 Ft² 150 PSI 300 F U Stamp.

In the early 1970s Tranter HES predecessor Kapp Apparatebau. 125 psi service side. Regarding the governing equations a LAB-sized model of this type of heat exchanger was designed and constructed.

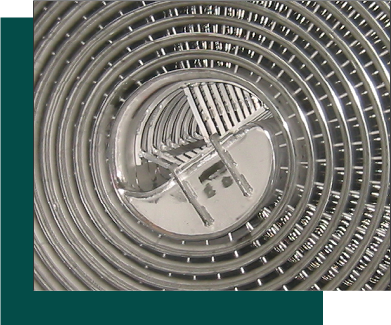

The E type spiral heat exchanger has one side in spiral flow and on side in axial flow. Currently the spiral is manufactured in a winding process using a D-shaped mandrel with the two strips being welded to a central plate and distance studs have replaced the steel bars. Used Heliflow Graham model 12WXF-16 spiral heat exchanger.

The Alfa Laval Type 2 spiral heat exchanger is used for 2-phase duties both condensing and evaporation re-boiling. In this configuration the. Originally the spiral plate heat exchanger was mainly used in the pulp and paper industry where fouling problems were frequent when using classical shell and tube exchangers or multi channels heat exchangers due to fibers in the effluents.

Alfa Laval spiral heat exchangers are designed to handle the toughest heat transfer challenges. A theoretical model predicting the thermal performance of the spiral-coil heat exchanger as a cooling and dehumidifying unit has been developed 6. Self-cleaning design High thermal efficiency.

Used Spiral Heat Exchangers for the Chemical Food and Pharmaceutical Packaging and Processing Industries Used Spiral Heat Exchangers from Special Projects International Quality Used Packaging and Processing Equipment. It provides optimum heat transfer and flow conditions for a wide variety of fluids with a built-in self-cleaning effect while keeping the overall size of the unit to a minimum. For more than 60 years it has been used in difficult services ranging from PVC slurry coolers to asphalt heaters.

GreenSpiralTM for sludge treatments is made of two concentric channels the spacings and width are controlled by special guideways and. To overcome these issues the spiral heat exchanger SPHE is a technology best suited for such applications with the potential for high fouling. Alberta Never used stored in Alberta.

Selection fabrication inspection testing and preparation for shipment of spiral plate heat exchangers for the petroleum petrochemical and natural gas industries. With its self-cleaning feature it can efficiently handle slurry viscous fluid even dirty media. Heat Exchanger Spiral 90 SF Sst 75 PSI S742581.

Used Graham Heliflow Heat Exchanger Model 15S6C-16L Model 15S6C-16L Spiral coil design installed within a cast iron casing. Performance of the spiral coil heat exchanger as a cooling and dehumidifying unit has been developed based on the assumption that the air is unmixed as it flows past each spiral coil turn. Yes National Board.

The spiral heat exchanger was developed in the 1920s for use in the paper industry by the Swedish engineer Curt Rosenblad. Sludge spiral heat exchangers are specially designed for digester sludge heating and heat recovery applications such as digested sludge heating raw sludge heating and heat recovery from effluents pasteurisation methanisation. A spiral heat exchanger can help processors avoid these problems.

We provide Quality Heat Exchanger Repair Custom Construction Precision Welding Detailed Heat Exchanger Cleaning Custom Heat Exchangers New Heat Exchanger Installations and offer 247 Emergency Services. For liquids and slurries spiral heat exchangers provide. As mentioned the SPHE design feature creates a turbulent flow preventing scaling.

Elanco Spiral Heat Exchanger Type DS. More so with its robust and efficient design spiral plate heat exchanger can be used for cooling heating or even heat recovery. Today practical maximum capacity of a standard Spiral Heat Exchanger is 400-600 m 2.

4 Alfa Laval spiral heat exchangers Alfa Laval spiral heat exchangers SHEs are based on an ingen-ious design. Elanco Spiral Heat Exchanger Type DS. SPIRAL HEAT EXCHANGER Built by Alfa Laval in 2003 Type.

Cross-flow condensing with lowest possible pressure drop. Used Graham Heliflow Heat Exchanger Model 15S6C-16L. Alternatively tubular centers are becoming more common.

Spiral heat exchangers are commonly used for projects involving liquids and slurries as well as those involving condensation and evaporation. For the first time a heat exchanger was available that allowed trouble-free heat transfer between particle-loaded process streams. Graham Heliflow Spiral Heat Exchanger.

In this article the performance and applications of a Spiral Plate Heat Exchanger are demonstrated. Galvanized Iron sheets were used as the heat transfer surfaces. On Site at Perry Hainesport NJ - USA Get a Quote View Details.

An SPHEs self-cleaning design can remove sludge due to the turbulent flow created during the SPHEs operation. In this configuration the spiral is always in a vertical position. Search our large inventory of used equipment - Spiral Heat Exchangers.

Also governing equation of heat transfer phenomena in such heat exchangers is discussed.

Spiral Plate Heat Exchangers Elanco Heat Transfer Systems

Sondex Spiral Heat Exchangers Danfoss

Pdf Performance Analysis Of Spiral Tube Heat Exchanger Semantic Scholar

Spiral Plate Heat Exchanger Hisakaworks

Spiral Plate Heat Exchangers Elanco Heat Transfer Systems

Heat Exchanger Alternative Applications Process Heating

Welded Spiral Plate Heat Exchanger

Nexson Sludge Spiral Plate Heat Exchanger With Customized Design

Spiral Plate Heat Exchanger Hisakaworks

Welded Spiral Plate Heat Exchanger

Spiral Plate Heat Exchanger Hisakaworks

Heat Exchanger Types Enggcyclopedia

Spiral Plate Heat Exchangers Elanco Heat Transfer Systems

Spiral Plate Heat Exchangers Elanco Heat Transfer Systems

Spiral Plate Heat Exchanger Hisakaworks

Comments

Post a Comment